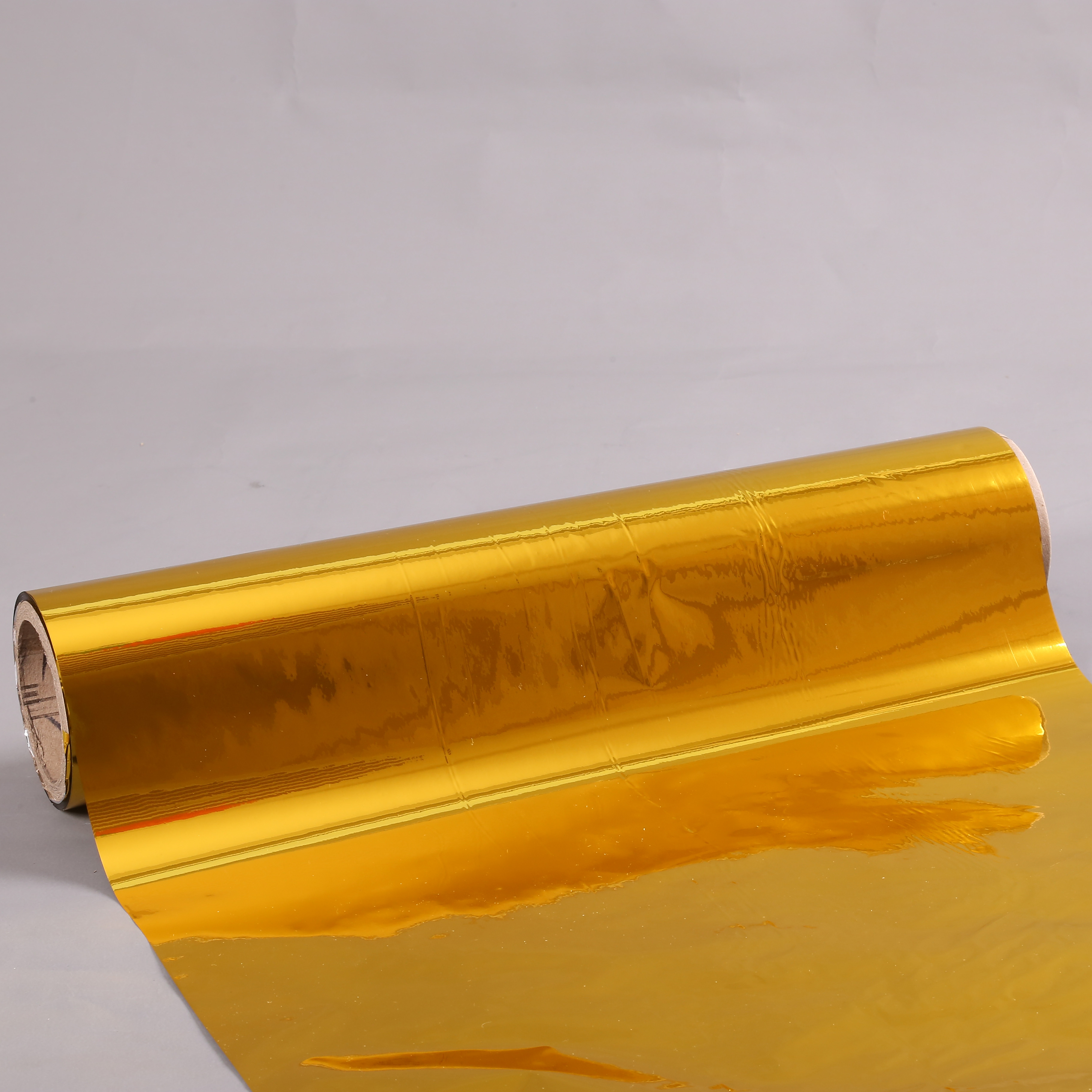

MPET film 12 micron for cardboard lamination

12 micron gold VMPET film for paperboard lamination

Substrate material: PET film

Thickness: 8 micron, 10, 12, 15, 23,36,100,125,150,175 micron etc

Max Width : 2100mm

Other spec can be customized according to your requirement.

Processing method: vacuum metalized

Color : Silver, Gold, Matte Silver, Matte Gold

Applications:packaging film, lamination film, water resistant barrier, reflective film:

Vacuum Metallized Plastic PET Film introduction

Hebei Senmi holographic CO.,LTD provides either decorative packaging or barrier to plastic film, then the film is laminated to other film or to paperboard. And, can be further enhanced by printing before it is converted into packaging. Besides normal print process, our polyester that surface with primer coated especially for UV curing ink. In addition to packaging applications, Metallized Film is used in numerous industrial applications.

Features

1) High strength

2) Good printability

3) Good barrier performance

4) Low oxygen permeability

5) Non-splash aluminum, wrinkle-free, no tramlines or smears

6) wide application range

Application

1.Packaging & Decorative Grade Film:

Face-Stock for self-adhesive, Gift-Wrapping, Glitter Powder, Metallic Yarn, Food-Packing, Laminated Paper/Paper board, Holographic Embossing.

2 Reflective film

For reflect the sunshine and make the best use of sunshine

3.Optical Grade Film :

Reflector in Liquid Crystal Display, LCD`s backlight unit, Light-Shielding.

4.Other Grade Film :

Cables Wrapping, Motors, Hot Stamping Foil, Transfer Printing, Release Agent, Leader Tape, OHP, Sheeting Protectors, Silicone Coating, Adhesive Tape, Solar Control Film.

|

Item |

Unit |

Standard |

Test method |

|

|

thickness |

mic |

12 |

ASTM D-374 |

|

|

Tolerance |

% |

±5 |

||

|

Tensile strength |

MD |

Mpa |

≥170 |

ASTM D-882 |

|

TD |

≥170 |

|||

|

Heat shrinkage (150℃,30min) |

MD |

% |

≤3.0 |

ASTM D-1204 |

|

TD |

≤3.0 |

|||

|

Elogation at break |

MD |

% |

≤200 |

ASTM D-882 |

|

TD |

≤200 |

|||

|

Surface tension |

Metal coating |

Mn/m |

≥38 |

ASTM D-2578 |

|

Film surface |

≥38 |

|||

|

Friction of coefficient |

—- |

≤0.80 |

ASTM D-1894 |

|

|

≤0.80 |

||||

|

Uniformity of aluminum layer |

% |

±10 |

X-RITE 361T |

|

|

Firm of aluminum layer |

% |

≥98 |

3M Tape |

|

|

Firm of coating layer |

% |

≥98 |

3M Tape |

|